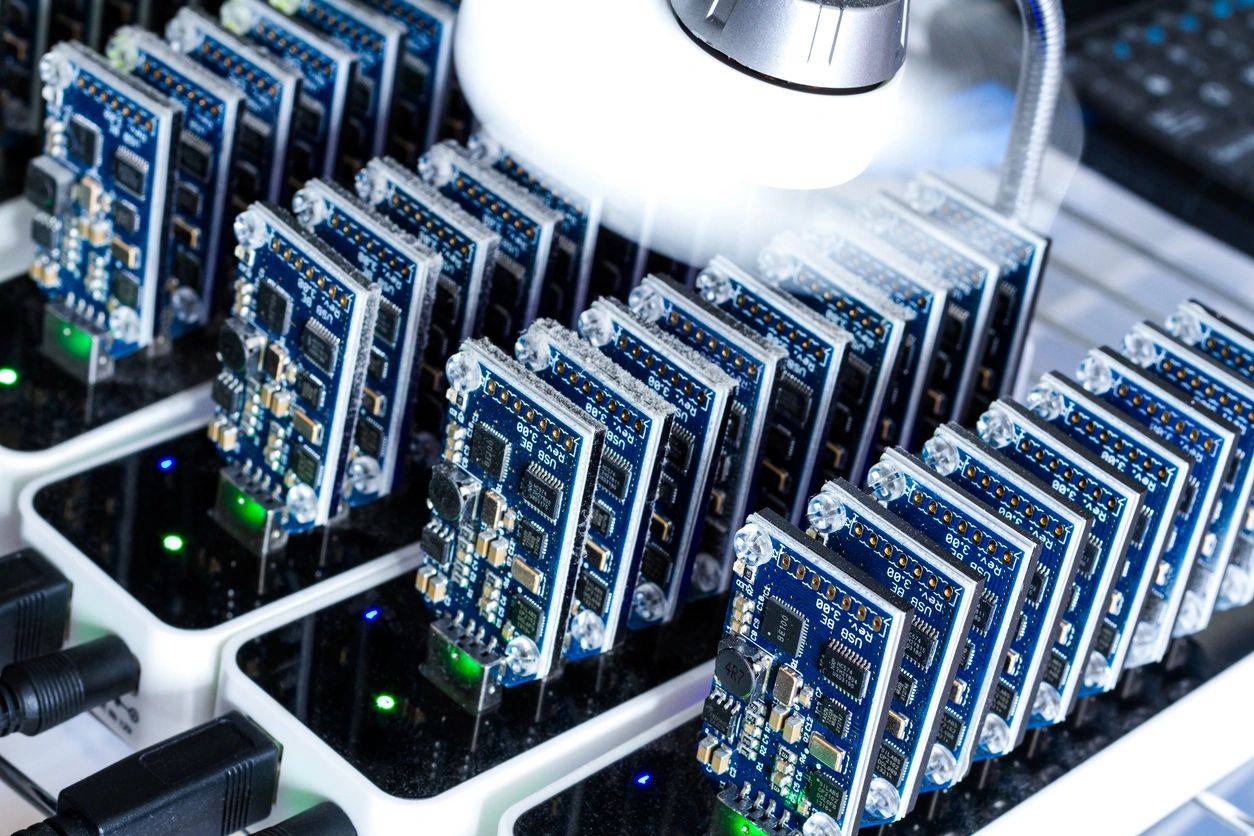

Printed circuit boards (PCBs) are essential in electronic devices, providing both physical support and electrical connections for components like processors, memory, and sensors. During manufacturing, proper testing is crucial to ensure PCBs function correctly and meet required specifications. Several testing methods exist, each with unique benefits and limitations.

In-Circuit Testing (ICT)

One common PCB testing method is in-circuit testing (ICT). This process involves connecting a specialized testing machine to the PCB to check each component and the overall board function. ICT is fast, can be automated, and is ideal for high-volume testing. However, it has limitations, such as difficulty detecting defects related to soldering quality.

Bed-of-Nails and Spring Probes

ICT can be performed using a Bed-of-Nails fixture, a tool designed for simple board-level testing. This setup often includes spring probes, which are specialized electrical connectors that make temporary contact with a PCB’s test points. These probes consist of a spring-loaded metal pin mounted on a carrier, which is then attached to a probe head compatible with the ICT machine.

When the probe head presses onto the PCB, the spring probes establish an electrical connection, allowing for efficient testing. Spring probes are widely used in ICT because they are cost-effective, easy to reconfigure, and adaptable for different PCB designs.

Functional Testing of PCBs

Functional testing is a method used to assess a PCB’s overall functionality by simulating its intended use. This process involves connecting the PCB to a computer or another device and running a series of tests to ensure it performs correctly. While functional testing takes more time than in-circuit testing (ICT), it provides a more comprehensive evaluation of the PCB’s performance.

Key Steps in Functional Testing

Functional testing can vary depending on the PCB’s requirements and characteristics. Common steps include:

Setting Up the Test Environment

Connect the PCB to a computer or test equipment.

Configure necessary software and hardware.

Writing Test Cases

Define specific scenarios to evaluate PCB performance.

Include tests for key tasks, environmental conditions, and component behavior.

Running the Tests

Execute test cases, either manually or with automated testing software.

Observe and document results.

Analyzing the Results

Determine if the PCB passes or fails.

Identify and address any defects.

Types of Functionality Tested

The functionality tested during PCB functional testing depends on its intended use. Common areas include:

Basic Electrical Functions

Powering on/off, data communication, and connectivity.

CTS custom test fixtures can use spring probing or other connectors for continuity testing.

Component-Level Functions

Ensuring LEDs, buttons, sensors, and screens function correctly.

CTS engineers identify critical components and develop the best testing methods for your custom fixture.

System-Level Functions

Evaluating complex operations, such as running an OS or controlling devices.

CTS test fixtures support customer-specified I/Os but do not provide programming.

Environmental Testing

Simulating conditions like temperature, humidity, and vibration.

CTS test fixtures integrate RF boxes, lights, motors, and other components as needed.

Reliability Testing

Running repeated tests to ensure long-term durability.

CTS fixtures are designed for hundreds of thousands to millions of cycles with replaceable wear components.

Ensuring Reliable PCB Testing

Regardless of the method used, a well-defined and thorough testing process is essential for ensuring PCB reliability and performance. This reduces the risk of defects and enhances the quality of electronic devices.

At Concentric Technology Solutions (CTS), we specialize in developing custom mechanical test fixtures tailored for both ICT and functional testing. Our solutions help streamline the testing process, improve accuracy, and ensure your PCBs meet all necessary specifications.